A culture of continuous improvement can create never-ending quality, efficiency, innovation, and profitability opportunities in any business. Process improvement is at the heart of this culture and we’re going to show you how to succeed on process improvement initiatives.

70% of process improvement initiatives fail due to reasons such as overcomplicating process improvement, poor leadership commitment or ownership, and poor communication. Keep in mind that not every process improvement initiative will be a huge success, but you can still take steps to stack the cards in your favour to achieve a better-than-30% success rate!

Unsurprisingly, it takes a winning approach to succeed. So, here are your three key focus areas to help you succeed at making process improvements in your department or organization.

1. Choose or lose.

Many process improvement initiatives fail due to poor process improvement selection. Just because a process has an opportunity for improvement doesn’t mean it should be improved.

Choosing the right process improvement opportunities is vital. Sometimes, the improvement activity cost outweighs the benefit of implementation. When you do not have a good selection practice and you end up choosing “anything shiny”, or nothing at all, you lose time, money, and credibility.

But how can you tell the difference? The answer is in having the right approach to identifying, ranking, and selecting your process improvement opportunities.

Identify improvement opportunities.

Process improvement opportunities are normally very easily identified by those who are closest to the process or the output. More specifically, listen to the feedback from your staff (regarding the process) as well as the voice of the customer (regarding the output). Create channels to funnel feedback to your improvement team or leaders, hold focus group sessions, conduct workshops, send out surveys, have a process improvement suggestion box. Collect the ideas and generate a list.

Rank improvement opportunities.

Once you have a list of process improvement opportunities, you need a method to rank and compare them.

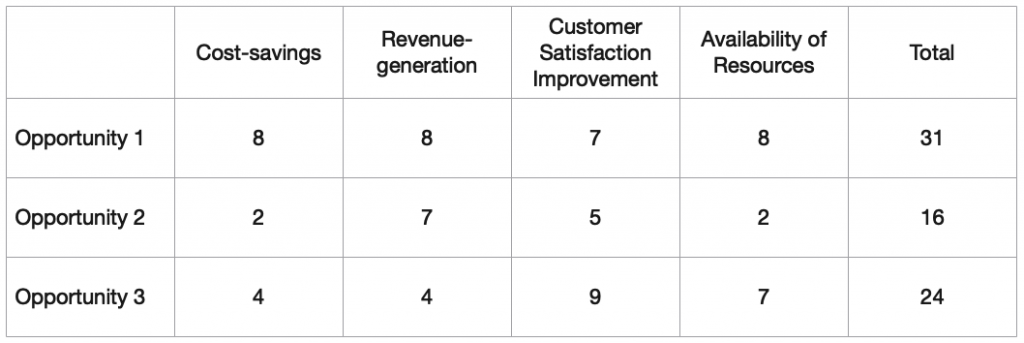

The easiest way to do this is to build a simple matrix. A matrix is a $10 word for a chart. A simple matrix looks like this:

Build it once and you can use it over and over again. You can even use the sample we’ve included so you don’t have to build your own.

The way the matrix works is this:

A. Create a table and list the improvement opportunities in the first column, beginning on the second row, moving downwards.

B. Identify what is important to the department or business. We’ll call this the “key drivers” and they may be items such as:

- cost-savings

- revenue generation

- customer satisfaction

- availability of resources (human and/or capital)

List the key drivers across the top, beginning in the second column, in the first row, moving towards the right.

When you’ve listed off all the key drivers across the top, add a “Total” column at the far end (right side).

C. Rank each key driver for each opportunity on a scale of 1 to 10 (1 being negative sentiment and 10 being positive sentiment). Add up the totals in the “Total” column and your ranking system is complete.

A matrix can involve many more options and can be considerably more sophisticated depending on your needs or the needs of your organization. You may also determine that you would like to weigh customer satisfaction more than cost-savings in your matrix, and you can do that as well, but I’ll saved weighted scoring for another lesson.

Select improvement opportunities.

And, finally, it’s time to make your selection(s). Referencing the sample matrix above, you can see that the business leader might choose Opportunity 1 to proceed with first, even though Opportunity 3 has the highest sentiment for improving customer satisfaction.

Use the matrix as a guide for improvement opportunity selection. There’s no need to be too rigid with the matrix, but that’s up to you. This approach creates a consistent practice for you to rank and compare opportunities, and it can be as simple or as complex as you’d like it to be.

The last thing to consider in selecting the right opportunity, is that sometimes improvements need to be made for regulatory, compliance, security, and/or system compatibility reasons. These key drivers may or may not be in your wheelhouse and may or may not be within your control. If these are not items listed on your matrix, don’t be surprised or feel put out if opportunities with those drivers suddenly skyrocket to the top of the list without warning.

2. Team All-In.

If having the right team of skilled experts is considered important (and it is), then having strong executive/sponsor commitment and support is considered critical to process improvement success.

I recall a project kickoff meeting between two executives and what the team took away from it was a huge shock!

We were in a project prioritization meeting. One of the VPs of Projects had just hired a new project manager to run a PCI Compliance Improvements Project. After the VP had finished introducing the new project manager, he went on to state that the PCI Compliance Improvements Project was a top priority for the organization. That’s when the train derailed…

A VP of Operations was present for the meeting and had recently been presented with a handful of organizational projects to support, which were also deemed, “top priority.” He proceeded with questions:

“Is the PCI Compliance Improvements Project higher priority than [insert project A name here]?”

“No.”

“Is the PCI Compliance Improvements Project higher priority than [insert project B name here]?”

“No.”

“Is the PCI Compliance Improvements Project higher priority than [insert project C name here]?”

“No.”

I kid you not, the VP of Operations went through this questionnaire with the names of three more projects. The answer to each question was, “no.”

How do you think that new project manager felt? What do you think of his chances for enthusiastic support and timely progress?

For true success, process improvements need to be a real priority – one that impacts your company’s bottom line and, therefore, has an influence on your teams’ year-end review performance criteria.

If your leadership is not yet ready to commit to that one, it may be best to circle back to process improvement when it becomes a true priority.

Team All-In Part 1: leadership commitment and support at the executive/sponsor level.

It’s not that the executive or sponsor should halt their regular work or quit their day job to lead the process improvement initiative; that is simply not their role. However, what does tend to happen is that the process improvement initiative may work independently of functional manager responsibilities and performance goals.

To encourage strong commitment and sustained process improvement success, the executive/sponsor should take steps to ensure the functional managers have a stake in the success of the process improvement initiative, and that the continuation of the improved process has a direct tie-in to their annual performance goals. Do not assume that your business leaders (functional managers) will support the ongoing success of the process improvement that you’ve spent time and money on. It’s possible they will, but you know the old adage about making assumptions – “when you ASSUME, you make an “ASS” out of “U” and “ME.”

Clarity is better than assumption. Whenever possible, draw direct lines between organizational priorities and annual performance goals, especially with functional leaders. Reward accordingly.

Team All-In Part 2: a skilled process improvement team.

You’ll want the following roles (note that some/multiple roles may be performed by the same individual):

- Project lead

- Process expert/analyst

- Business analyst

- Change Management analyst

- Process owner

- Functional leads or managers

- Subject Matter Expert(s)

When you put the working team together, you don’t just choose Bill, Maria, and Jessica because they have more time than everyone else. Choosing the process improvement team is comprised of selections based on the following criteria/need: leadership, experience, process improvement skillset, and familiarity with the processes.

So, to recap, Team All-In is a winning team comprised of:

a. executive leadership commitment and sponsorship.

b. a skilled process improvement team.

3. Measure monetization.

This is, arguably, the toughest challenge for some organizations – how do we measure success? What if we do not use operational metrics today? What if our processes are all manual tasks? What if we do not have the technology to support automated reporting?

The key to measuring success comes down to finding a way to connect the dots back to the company’s finances. Sometimes this is simple and sometimes it can be a bit of a riddle to solve, like following breadcrumbs.

If you’ve ever hired a contractor, you may be familiar with the term, “time and materials.” You can use this term to help you figure out how a process impacts your company’s bottom line. In some cases, the numbers will be precise, in other cases they will be approximations. In some cases the metrics and reports can be automated, and, in other cases, they will be manually generated.

Anything that is product-based is considered material. This includes products you purchase for the office and utilities or supplies that you purchase to support the manufacturing of a product.

Anything non-product-based is considered time. Human Resource salaries and labour, training, shipping and equipment servicing are all examples of time-based costs.

Use this approach as a guide to help you create performance metrics.

Let’s illustrate this with an example:

Let’s say you work for a company that manufactures hand sanitizer and you suspect that that a high number of defective batches are costing your company in time, money and brand reputation. Your process improvement team has identified poor quality control as the culprit and you wish to build your case to determine whether or not it is worth it to improve quality control.

What’s an appropriate quality metric to use for a quality control improvement initiative and what is the potential financial impact? Let’s look at some of the Time & Materials costs:

Time: utilities costs, human resource (sales, support and operations) labour costs, equipment servicing, shipping, administration.

Materials: isopropyl alcohol, glycerin, hydrogen peroxide, distilled water, plastic containers, shipping containers, manufacturing equipment.

When you have an unsatisfactory batch of hand sanitizer shipped off to a customer, there is a cost associated with the customer returning the product and your company sending them a satisfactory replacement.

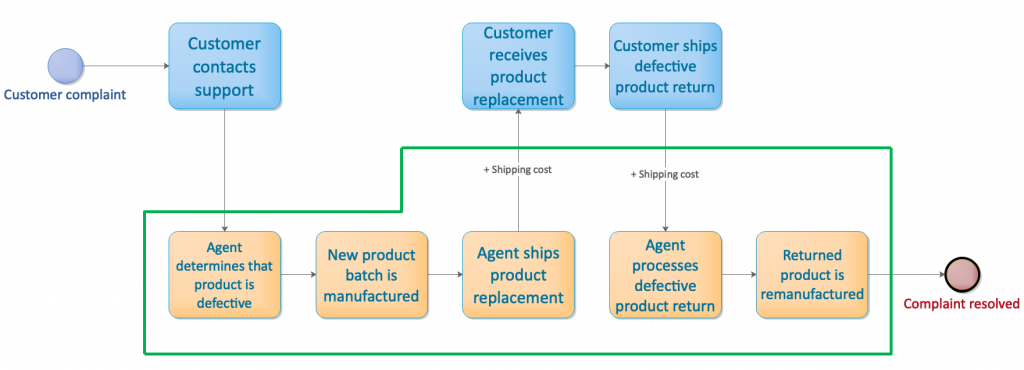

You analyze the steps for processing returns/replacements and it may look like this:

The activities within the green border are efforts and costs incurred by your company, for rework due to a defective product.

Let’s approximate some conservative numbers and perform some basic calculations:

| Hours | Rate | Totals | |

| Agent (call centre) labour | 2 | $25 per hour | $50 |

| Operations (remanufacturing) labour | 2 | $25 per hour | $50 |

| Shipping costs | 2 (units) | $10 per unit | $20 |

| Total cost per defective batch | $90 |

Ok, so let’s say the cost of rework per defective batch is $90. How can you measure the actual impact and cost-savings to your company?

If you have stats on the number of defective batches per shipment, use those for your actual cost impact calculation. Then, set a lower target to achieve and update the calculation to understand the reduced cost to your company. If you do not know your defective batch rate and/or do not track it, you can estimate it for now, and begin tracking it as part of your process improvement plan.

Finally, determine (through your process improvement team) how much the improvement activity will cost to implement and compare it to how much your company saves year over year (e.g., the next 3 to 5 years).

Now you’ve determined a way to put a cost and ROI to a process improvement opportunity. You can use the same general approach if your company is service-based, rather than product-based.

Try out this exercise with a business process problem that you have today and leave a comment to let us know if it helped, or if you have suggestions for improvements to the approach!

Be safe, be healthy and be efficient.

___

Process Primer is an independent business and IT process consulting company. Our views and approaches are based on the Lean Six Sigma process improvement methodology as well as our own experiences in organizational leadership as well as business process management and automation.

Alwin

Your Friendly Neighbourhood Process Consultant